4 Layer High Frequency PCB on 2 Cores of 32mil RO4003C and 12mil RO4450F for Ultrahigh Frequency Couplers

(Printed circuit boards are custom-made products; the images and specifications shown are for reference only.)

Introduction

Hello Everyone,

Good day!

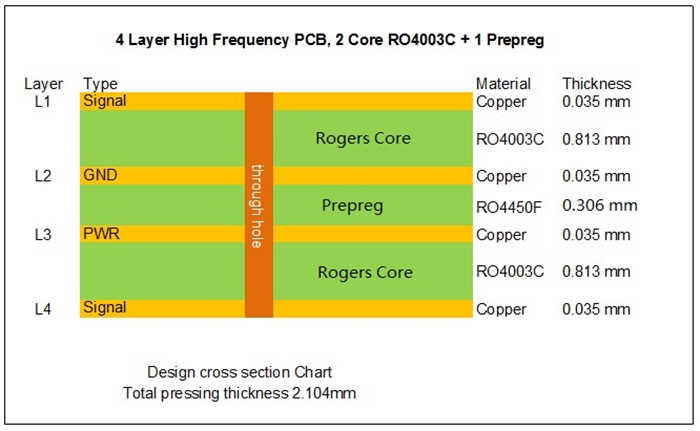

Today, we will discuss a specialized 4 layer high frequency PCB. This PCB is constructed using two sheets of 0.813mm (32mil) RO4003C cores, combined with one sheet of RO4450F prepreg, specifically designed for ultrahigh frequency coupler applications. Below is the stack-up configuration.

Typically, multilayer Rogers high-frequency PCBs are composed entirely of high-frequency materials, including prepreg adhesives. The RO4003C family features six core thickness options, ranging from 8mil (0.203mm) to 60mil (1.524mm).

RO4003C Thickness |

Metric |

8mil |

0.203mm |

12mil |

0.305mm |

16mil |

0.406mm |

20mil |

0.508mm |

32mil |

0.813mm |

60mil |

1.524mm |

The stack-up of four layers can be configured in various ways, providing design flexibility.

Specifications of the Board:

| Item | Specification |

|---|---|

| Base Material | RO4003C 32mil + RO4450F 12mil Prepreg |

| Layer Count | 4 Layers |

| Type | Castellation holes (half holes) on the edge |

| Format | 113mm x 80mm = 1 type = 4 pieces |

| Surface Finish | Immersion gold |

| Copper Weight | Outer layer 35 μm / Inner layer 35 μm |

| Solder Mask / Legend | None / None |

| Final PCB Height | 2.1 mm |

| Standard | IPC 6012 Class 2 |

| Packing | 20 panels per shipment |

| Lead Time | 10 working days |

| Shelf Life | 6 months |

Features and Benefits:

1.Outstanding High-Frequency Performance: Achieved through low dielectric tolerance and loss.

2.Automated Optical Inspection (AOI): Ensures quality control.

3.Comprehensive PCB Solutions: From prototype development to mass production.

4.Production Capacity: Capable of processing 30,000 square meters monthly.

5.Diverse PCB Types: Ability to produce 8,000 different PCB designs each month.

6.Extensive Experience: Over 16 years in the PCB manufacturing industry.

Applications

GPS Antennas

WiFi Amplifiers

Power Amplifiers

RF Transceivers

TV Antennas

Radar Data Acquisition Converters

Spread Spectrum Devices

Attenuators

Appendix: Properties of RO4003C

RO4003C Typical Value |

|||||

Property |

RO4003C |

Direction |

Units |

Condition |

Test Method |

Dielectric Constant,εProcess |

3.38±0.05 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 Clamped Stripline |

Dielectric Constant,εDesign |

3.55 |

Z |

|

8 to 40 GHz |

Differential Phase Length Method |

Dissipation Factortan,δ |

0.0027 |

Z |

|

10 GHz/23℃ |

IPC-TM-650 2.5.5.5 |

Thermal Coefficient of ε |

+40 |

Z |

ppm/℃ |

-50℃to 150℃ |

IPC-TM-650 2.5.5.5 |

Volume Resistivity |

1.7 x 1010 |

|

MΩ.cm |

COND A |

IPC-TM-650 2.5.17.1 |

Surface Resistivity |

4.2 x 109 |

|

MΩ |

COND A |

IPC-TM-650 2.5.17.1 |

Electrical Strength |

31.2(780) |

Z |

Kv/mm(v/mil) |

0.51mm(0.020") |

IPC-TM-650 2.5.6.2 |

Tensile Modulus |

19,650(2,850) |

X |

MPa(ksi) |

RT |

ASTM D 638 |

Tensile Strength |

139(20.2) |

X |

MPa(ksi) |

RT |

ASTM D 638 |

Flexural Strength |

276 |

|

MPa |

|

IPC-TM-650 2.4.4 |

Dimensional Stability |

<0.3 |

X,Y |

mm/m |

after etch+E2/150℃ |

IPC-TM-650 2.4.39A |

Coefficient of Thermal Expansion |

11 |

X |

ppm/℃ |

-55℃to288℃ |

IPC-TM-650 2.4.41 |

Tg |

>280 |

|

℃ TMA |

A |

IPC-TM-650 2.4.24.3 |

Td |

425 |

|

℃ TGA |

|

ASTM D 3850 |

Thermal Conductivity |

0.71 |

|

W/M/oK |

80℃ |

ASTM C518 |

Moisture Absorption |

0.06 |

|

% |

48hrs immersion 0.060" |

ASTM D 570 |

Density |

1.79 |

|

gm/cm3 |

23℃ |

ASTM D 792 |

Copper Peel Stength |

1.05 |

|

N/mm |

after solder float 1 oz. |

IPC-TM-650 2.4.8 |

Flammability |

N/A |

|

|

|

UL 94 |

Lead-free Process Compatible |

Yes |

|

|

|

|